Stainless Steel Processing

At Midway Metals, our national network of service centres allow the fast and flexible processing of high quality, high performance stainless steel to suit different specifications and applications.

Through our unmatched processing capabilities, we value-add to stainless steel through our cut-to-length, slitting, polishing and coating services. From this, we’re able to offer customers a full range of stainless steel materials and products in varying lengths, widths and finishes from the one supplier.

We process and produce:

- Sheets

- Plates

- Coils

- Slit bands

- Polished sheets and coils

- Flat bars

In addition, we

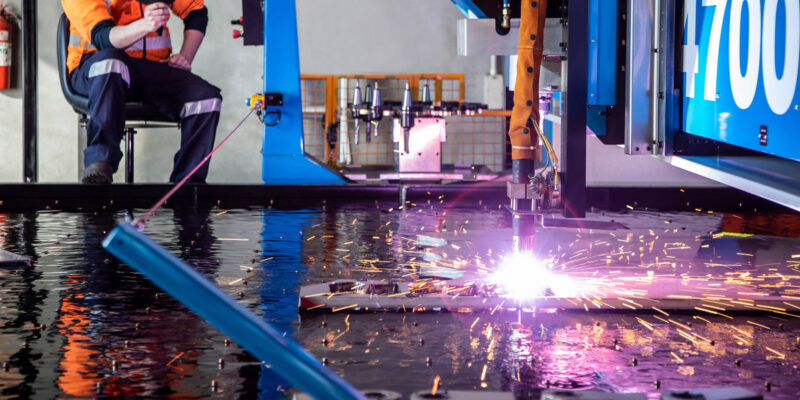

- Plasma cut and drill plates to size

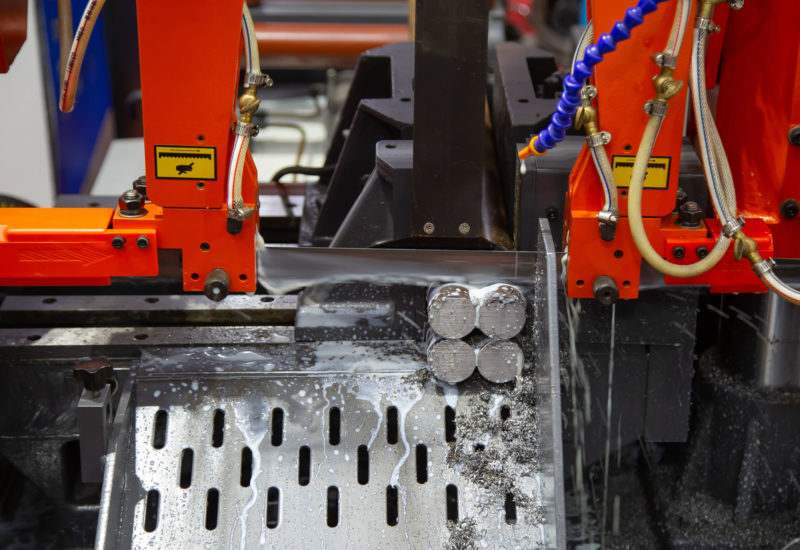

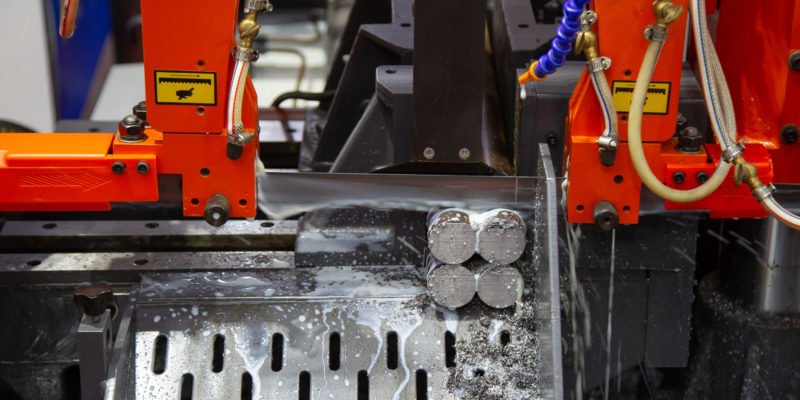

- Band saw cut long products to length

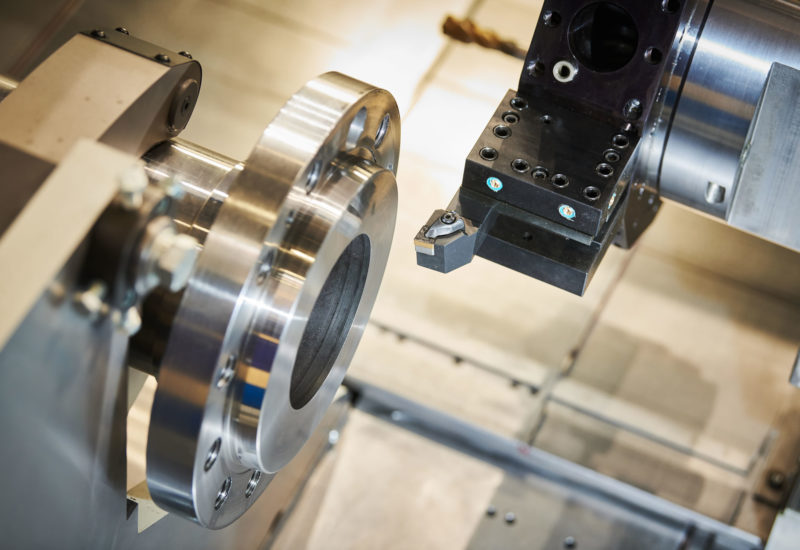

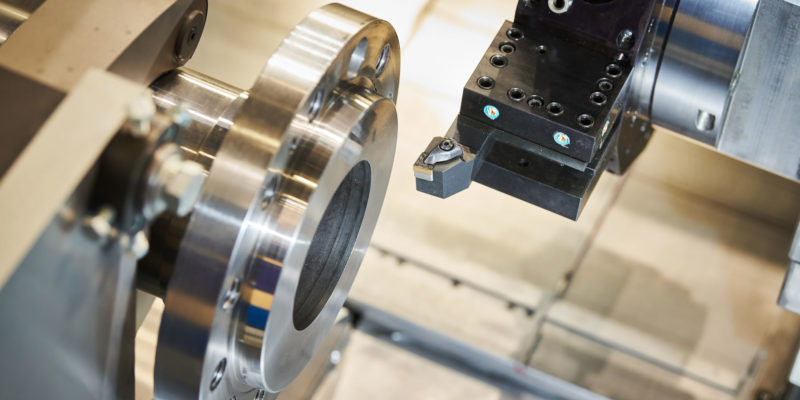

- Manufacture AS2129 flanges on our CNC machines.

Our local processing allows us to meet customer specifications, so Australian industry has the stainless steel materials and products they need, when they need it, at the quality standard they expect.

Services

-

Blanking Line

State-of-the art Red Bud blanking lines that produce stainless steel sheets with superior flatness.

-

Slitting Line

Australia’s largest high speed, high performance coil-to-coil slitting line which conveniently slits coils to any specified width.

-

Flat Bar

Australia’s only slit-rolled edge flat bar machine delivers fast, seamless processing.

-

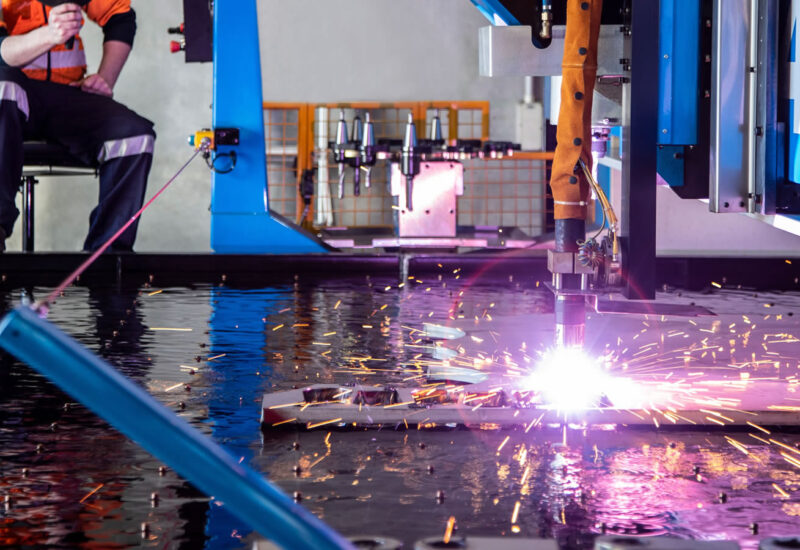

Plasma Cutting

Australia’s largest capacity for innovative, high precision plasma cut plate processing.

-

-

-

Sheet & Coil Polishing

For architectural appearance or low surface roughness, our polishing services ensure an optimum finish.

“We go above and beyond to meet our customer’s needs, priding ourselves on our quality and innovation, speed and precision.”

Frequently Asked Questions

How Do You Manufacture Stainless Steel?

Our stainless steel is sourced from a carefully-selected network of high quality supply mills worldwide. Stainless steel is an iron chromium alloy with other added elements.

The alloy is made in many different forms and further produced in different dimensions. At Midway Metals, we process several types of stainless steel into different products depending on your applications.

Where Is Stainless Steel Manufactured?

Stainless steel is manufactured throughout many countries all over the world.

A large portion of the stainless steel we import is cut, slit, and polish to different specifications with industry-leading equipment at our processing facilities in Australia.

What Processes are available at Midway?

With our cutting-edge technology and equipment, we utilise different processes for making stainless steel to suit your applications. We are equipped with blanking lines, slitting lines, flat bars, plasma and bandsaw cutting, flange processing, and sheet and coil polishing based to meet your requirements.

At Midway Metals, you can trust us to deliver the stainless steel you need.

What Is Used to Make Stainless Steel?

Stainless steel is made primarily from iron and chromium. Other alloying elements, such as nickel are added to enhance the corrosion-resistant properties or other attributes that makes stainless steel an effective and efficient material to use.. The degree to which a particular element is added results in different attributes being enhanced and varying grades of stainless steel.

At Midway Metals, we can provide all your stainless steel needs.