Stainless steel tubing is an indispensable component across industries due to its unmatched durability, corrosion resistance, and wide range of sizes and dimensions. With its excellent mechanical properties and hygienic properties, stainless steel tubing is suitable for high-pressure environments, marine applications, and decorative uses. Selecting the right tube dimensions, including wall thickness, outer diameter, and interior measurements, ensures optimal performance for the intended application.

This guide provides a comprehensive overview of stainless steel tubing sizes, grades, and key terms to help you make informed choices for various industrial, architectural, and structural needs.

What is Stainless Steel Tubing?

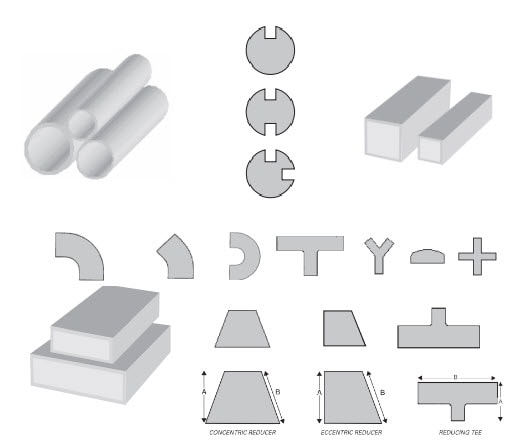

Stainless steel tubing, made from high-quality stainless steel alloys, is a versatile and durable material. Commonly supplied in round, square, and rectangular shapes, this tubing is widely used for its superior corrosion resistance and good machinability. Stainless steel tubing can be found in applications ranging from structural frameworks to hygienic and sterile systems in the food and medical industries.

Depending on the intended use, tubing is available in welded or seamless forms. Welded tubing is manufactured by joining flat steel strips to form a tube, while seamless tubing is extruded, providing higher strength and a uniform surface. Additionally, stainless steel tube may feature a mill finish, polished mirror surface, or other finishes tailored to specific decorative applications.

Stainless Steel Tubing Dimensions Explained

When discussing stainless steel tube dimensions, key measurements include the outside diameter (OD), inside diameter (ID), and wall thickness. These measurements collectively determine the tubing’s performance, rigidity, and suitability for specific applications. OD is crucial for ensuring compatibility with fittings, while ID defines the flow capacity of fluids or gases. Wall thickness plays a vital role in structural strength, weight, and resistance to high-pressure environments.

Accurate measurement of these dimensions is essential, particularly in industries requiring tight tolerances. Stainless steel tubing is often measured in millimetres (mm) for precision and consistency. Standardised tables provided by manufacturers typically outline the range of sizes, lengths, and tolerances, ensuring that users can select the appropriate dimensions for their needs.

Common Stainless Steel Tube Sizes

Stainless steel tube sizes vary significantly to meet the diverse requirements of different industries. Round tubes are commonly used in structural and construction applications, while rectangular tubes and square shapes are preferred for decorative or architectural projects. Popular sizes include diameters ranging from a few millimetres to several inches, with wall thicknesses tailored for lightweight or heavy-duty applications.

Manufacturers also supply customised sizes to accommodate unique needs. These customised stainless steel tube sizes are especially useful in specialised industries, such as marine environments or high-pressure systems. The availability of a broad range of sizes ensures that stainless steel tubing can be adapted to meet the most challenging requirements.

Applications of Stainless Steel Tubing

Stainless steel tubing is valued for its durability and versatility in a wide array of applications. In construction, it is used for structural support due to its strength and corrosion resistance. Marine environments benefit from stainless steel’s ability to resist saltwater corrosion, making it an ideal choice for shipbuilding and offshore platforms.

In industrial applications, stainless steel tubing is suitable for transporting fluids in high-pressure environments, with its rigidity and straightness ensuring efficient operation. Healthcare and food industries appreciate its hygienic sterile properties, as it is easy to clean and resistant to microbial contamination. Furthermore, stainless steel tubing’s mirror-like finishes and decorative shapes make it a popular choice for aesthetic applications in architecture and interior design.

Selecting the Right Stainless Steel Tube

Choosing the right stainless steel tube requires careful consideration of several factors. First, evaluate the grade of stainless steel to ensure it meets the operational requirements. Common grades like 304 and 316 provide excellent corrosion resistance, with 316 being particularly suitable for harsh environments like marine applications.

Next, consider the tube dimensions, including OD, ID, and wall thickness, to ensure compatibility with fittings and the intended use. For high-pressure systems, thicker walls and seamless tubing are often recommended to withstand extreme conditions. Custom sizes may also be necessary for specialised applications, and consulting with a reliable manufacturer or supplier ensures quality and precision.

Lastly, pay attention to the finish. For decorative purposes, a polished or mirror-like surface enhances the appearance of the tubing, while industrial uses may prioritise mill finish for cost-efficiency.

Advantages of Stainless Steel Tubing

Stainless steel tubing is prized for its corrosion resistance, making it suitable for both indoor and outdoor environments. Its durability ensures long-term performance, even in high-pressure or extreme temperature conditions. The material’s good machinability and formability allow it to be bent, shaped, or welded into complex configurations, accommodating diverse project requirements.

Another significant advantage is its sustainability. Stainless steel is recyclable, reducing environmental impact while maintaining its structural integrity over multiple lifecycles. This makes it a preferred choice for environmentally conscious projects and industries.

Midway Metals’ Stainless Steel Tube Products

Midway Metals offers an extensive range of stainless steel tube products designed to meet diverse industry needs. Their product line includes:

Welded Round Tube

Welded round tubes are a versatile option for structural and architectural applications. Midway Metals offers a variety of sizes and finishes, ensuring you have the right product to meet specific requirements. These tubes are available in different diameters and wall thicknesses, making them suitable for a wide range of uses in various industries.

Specifications:

- Standards: ASTM A554, ASTM A269, AS1528

- Lengths: 6 metres

- Finishes:

- Mill Finish (W)

- Polished 320 Grit (P)

- Polished Midway Mirror (M)

- Annealed Polished 600 Grit (PA)

- Food Polished 320 Grit (F)

The different finishes available, such as Polished Midway Mirror and Food Polished 320 Grit, offer enhanced durability and a clean appearance, perfect for both industrial and decorative applications.

Architectural Tube

Architectural tubes are specially designed to meet the needs of aesthetic applications, offering both functionality and visual appeal for visible structures. These tubes are perfect for use in projects where appearance and durability are equally important. Available in various profiles and finishes, architectural tubes are commonly used in railings, balustrades, decorative frameworks, and other architectural applications.

Specifications:

- Standards: ASTM A554

- Length: 6 metres

- Finishes:

- Polished Mirror (M)

- Polished 400 Grit (P)

Available Types:

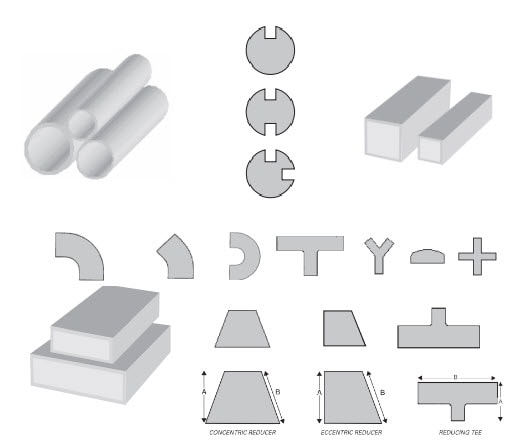

- Slotted Hand Rail – Slotted handrails are designed for structural and decorative purposes, offering an elegant and modern aesthetic. These tubes come in different sizes and slot types, suitable for various architectural and design needs.

- Oval / D Tube – Oval and D-shaped tubes add a unique, smooth profile to architectural designs, enhancing the aesthetics while maintaining strength and versatility. They are commonly used in railing systems and as decorative elements in modern structures.

- Triangular Tube – Triangular tubes offer a distinctive, angular shape that can be used for both functional and ornamental purposes. Their unique form makes them suitable for modern and contemporary architectural designs.

These architectural tubes are available in high-quality finishes, including Polished Mirror and Polished 400 Grit, ensuring a clean, refined appearance for visible structures.

Welded Square & Rectangular Tube

These tubes are versatile for both structural support and decorative applications. Available in various sizes and finishes meeting diverse project needs.

- Specifications: ASTM A554

- Length: 6 metres

- Finishes: Polished 180 Hairline (SBP), Polished 400 Grit (400)

These square and rectangular tubes are ideal for both heavy-duty applications and aesthetic projects.

For the selection of tube sizes available please refer to our on-line catalogue or contact our sales people who are waiting for your call.

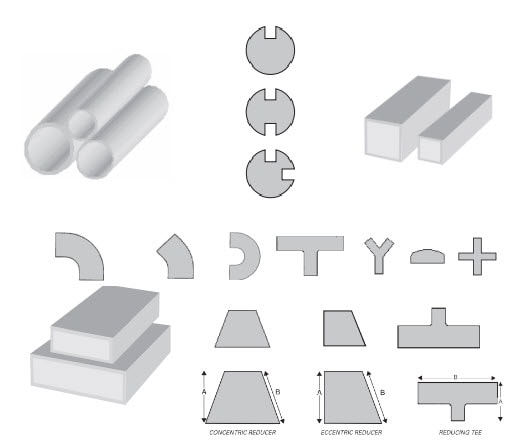

Tube Fittings

Tube fittings from Midway Metals ensure seamless integration and assembly for a wide range of stainless steel tubing systems. Engineered to meet Australian Standard 1528 (Part 3 – 1975), these fittings deliver precision and reliability for industrial and commercial applications.

Specifications:

- Standards: Australian Standard 1528, Part 3 – 1975

- Bends CLR: 1.50

- Finish Options:

- Bends: Unpolished & Polished

- Other Fittings: Polished

Available Fittings:

- 90° Bends

- 45° Bends

- 180° Bends

- Equal Tees

- Y-Pieces

- Caps

- Crosses

Size Range:

- Sizes: From 1/2 inch (12.7 mm) to 12 inches (305 mm)

- Wall Thickness:

- 1.6 mm

- 2 mm

Material Options:

- Grades:

- 304 Stainless Steel

- 316 Stainless Steel

These fittings cater to a variety of applications, including fluid transfer, structural support, and custom assemblies. Their polished and unpolished options provide flexibility for both aesthetic and functional demands.

Hygienic Fittings

Hygienic fittings are engineered to meet specific dimensional standards for seamless integration in sterile environments. These fittings cater to food, beverage, and pharmaceutical applications, ensuring strict compliance with hygiene standards.

BSM/RJT Fittings

- Sizes: Range from 25.4 mm to 152.4 mm.

- Components: Include round slotted nuts, hex nuts, male parts, and O-rings (EPDM, Teflon, Viton).

- Compatibility: Dimensions adhere to AS1528, Part 4 – 1976 standards.

Hygienic Flat Face Fittings

- Sizes: Available in diameters from 12.7 mm to 152.4 mm.

- Options: Include flat face liners, lip-removed male parts, and seals (EPDM, Teflon).

Tube Clamps

- Sizes: Cover a range from 12.7 mm to 304.8mm.

- Designs: Plain, bossed, long tang, and double-bolted variations.

Triclover Fittings

- Sizes: Available from 19.05 mm to 152.4 mm.

- Components: Include clamp bodies, ferrules, blank caps, and seals (EPDM, Buna, Teflon, Viton).

- Standards: Conform to AS1528, Part 2 – 1976.

This precise dimensional information ensures compatibility and reliability across applications, maintaining sterile and efficient operations.

Conclusion

Understanding stainless steel tubing sizes and dimensions is essential for making informed decisions in various industries. From wall thickness to outside diameters, every measurement impacts the tubing’s performance and suitability for its intended application. Whether you require a round tube for structural projects, a rectangular tube for decorative purposes, or a customised option for a high-pressure environment, stainless steel tubing offers the versatility and reliability you need.

By selecting the right dimensions, grade, and finish, you can ensure optimal performance and longevity for your projects. Stainless steel tubing remains a trusted material, combining strength, durability, and sustainability to meet the demands of modern industry and design.

For a comprehensive guide to the sizes, dimensions, and types of our tubing and fittings, please refer to our catalogue. This resource will help you select the perfect stainless steel solution for your needs.