Welding stainless steel is a critical skill for many metalworking projects due to its exceptional corrosion resistance and durability. Whether you’re using MIG welding stainless steel for its speed and versatility or opting for TIG weld stainless steel for precision and clean finishes, understanding the nuances of these techniques is essential. This guide provides a comprehensive overview of the process, ensuring your stainless steel welds are strong and reliable. From selecting the right consumable grade to mastering different welding methods, we cover all the essentials to help you achieve professional results. Additionally, understanding the various stainless steel grades, such as austenitic stainless steel, ferritic stainless steel, martensitic, and duplex stainless steel, will help you choose the right material for your project.

A Quick Guide on Welding Stainless Steel:

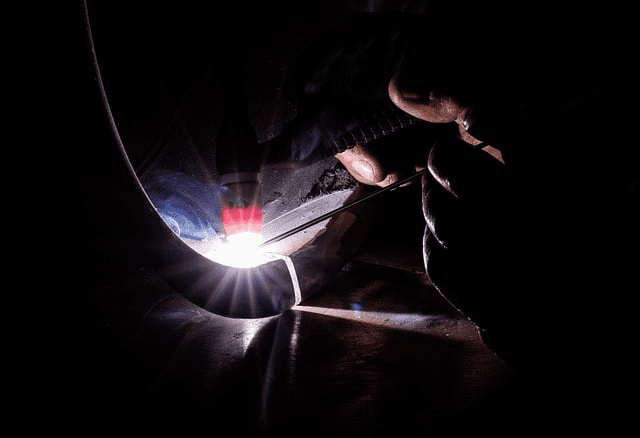

Protect Yourself:

Welding stainless steel or any metal absolutely requires wearing the right safety gear. A welding helmet and gloves are essential, and other protective clothing is also advisable. Make sure you keep away from the fumes while you are welding, and read all relevant manufacturers, employers and safety procedures before you start.

Fit Up:

When you’re welding stainless steel, selecting the right joint design and fitting it up properly is crucial. Your welding position and access to the joint, the thickness of your stainless steel, and the required strength of the weld are all things you should consider. Depending on what you’re welding, you may need to clamp your steel in place while you weld.

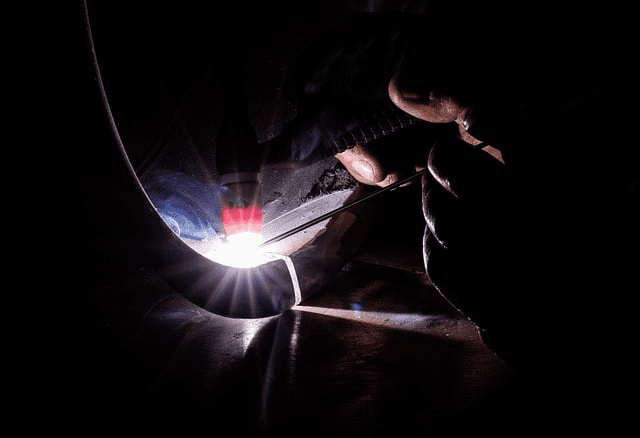

Weld Process:

There are several welding processes available. TIG welding stainless steel offers the advantage of minimal finishing work after welding. Additionally, ‘MIG welding’ includes two main types: Flux Cored Arc Welding and Gas Metal Arc Welding. The MIG welding process is versatile and suitable for various metal thicknesses. Flux Cored Arc Welding ensures a stable arc and deoxidation. It’s crucial to consider that stainless steel retains heat during MIG welding, impacting technique and weld quality. Therefore, selecting the right inert shielding gas and wire is essential, particularly for welding stainless steel with the same alloy. This prevents cracking and ensures the joint matches the base metal. Adjusting the welder’s parameters based on the steel and chosen process further optimises the welding outcome.

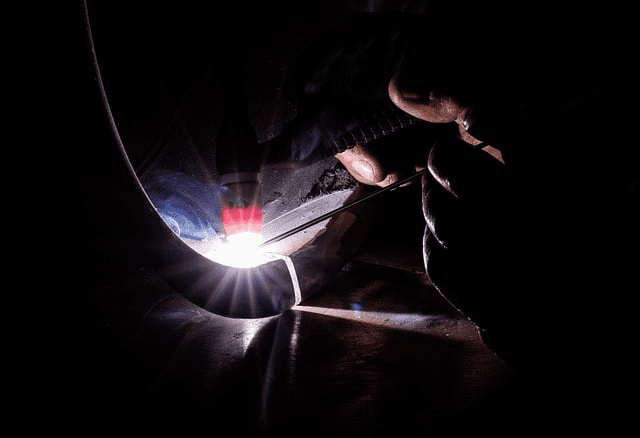

Welding and Finishing:

Make sure the surface of the steel is clean. That means free of paint, dirt, oil or anything else foreign. Wearing gloves while welding stainless steel will prevent oil from your hands getting onto the area you’re welding. Preheating is important for welding some stainless steel and less important for others. Preheat according to the type of stainless steel you’re using. Once all that preparation is done, you’re ready to weld. Postheat will prevent cracking by slowing down the cooling process. It also relieves stresses in the steel. This is particularly important if the steel you’ve welded is thick. Depending on your welding process, if there’s slag, remove it by chipping or grinding it off.

Is welding stainless steel difficult

Welding stainless steel may seem daunting, but with the right knowledge and techniques, it can be mastered. Stainless steel welds find application across a wide range of industries and projects, including the fabrication of stainless steel alloys for aerospace components, the construction of stainless steel pipes for plumbing and industrial systems, and the creation of durable structures using various grades of stainless steel. Additionally, welding stainless steel presents unique challenges compared to welding mild steel due to its higher heat conductivity and susceptibility to distortion. However, with proper preparation and understanding of the welding process, achieving high-quality stainless steel welds is achievable for both professionals and hobbyists alike.

Unlock the Potential of Stainless Steel Welding

Ready to take your stainless steel welding skills to the next level? Explore Midway Metals‘ extensive range of stainless steel and welding products and discover why we’re the preferred choice for professionals worldwide. With our dedication to innovation and customer satisfaction, Midway Metals is your trusted partner in mastering the art of stainless steel welding.